Na logística moderna e na gestão de armazéns, as empilhadeiras desempenham um papel indispensável. Como ferramenta importante para melhorar a eficiência do trabalho e garantir a segurança no manuseio, a construção e a manutenção de peças para empilhadeiras, especialmente as

sistema de mastro

, são cruciais. Hoje, exploraremos profundamente a composição estrutural das peças do mastro da empilhadeira para ajudar os leitores a compreender rapidamente o design requintado e a funcionalidade desta peça fundamental.

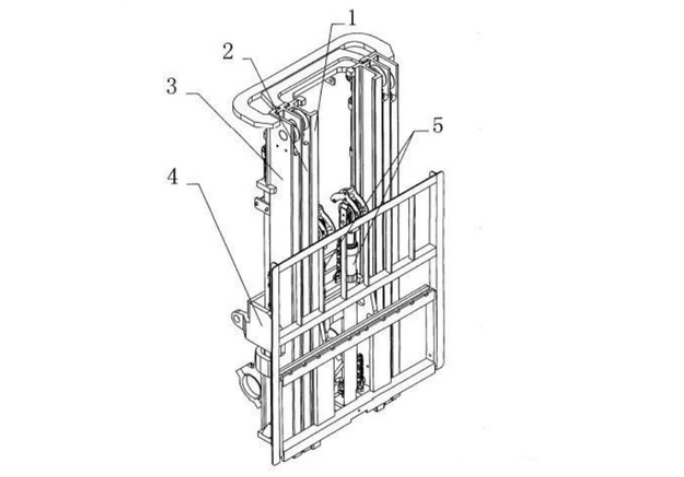

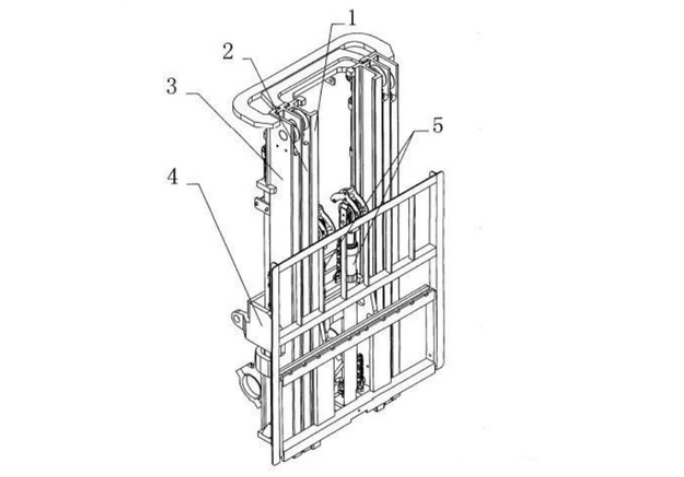

Os principais componentes de um mastro de empilhadeira

01

Mastros internos e externos:

Constituem a estrutura principal do mastro da empilhadeira, suportam o peso das mercadorias e garantem o movimento vertical de elevação ou inclinação do garfo através de seu projeto estrutural

02

Garfo:

A parte que entra em contato direto com a mercadoria possui diferentes tipos e tamanhos, de acordo com as características da mercadoria. O garfo é instalado na estrutura do garfo e é o principal responsável pela operação de movimentação da empilhadeira.

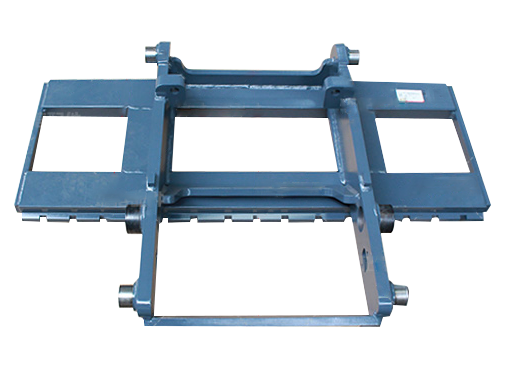

03

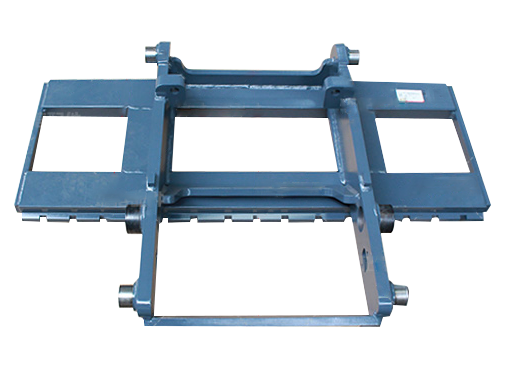

Estrutura do garfo:

Conecta o garfo e o mastro e se move ao longo dos trilhos-guia do mastro para fazer o garfo e as mercadorias subirem e descerem.

04

Corrente e roda dentada:

A corrente contorna a roda dentada na parte superior do mastro e puxa a estrutura do garfo e o garfo para cima ou para baixo através do acionamento do cilindro de elevação. É o sistema de transmissão de força usado pela empilhadeira para levantar as mercadorias.

05

Cilindro de elevação e cilindro de inclinação:

O cilindro de elevação é responsável por empurrar a corrente para conseguir levantar as mercadorias; o cilindro de inclinação controla a inclinação frontal e traseira do mastro para facilitar o empilhamento preciso e a coleta das mercadorias com o garfo

Princípio de funcionamento do mastro da empilhadeira

O mastro da empilhadeira foi projetado para fornecer uma posição estável e

solução eficiente de movimentação de carga

Quando o operador inicia a função de elevação da empilhadeira, o sistema hidráulico injeta líquido no cilindro de elevação para empurrar a haste do pistão para cima. O movimento da haste do pistão é transmitido à roda dentada através da corrente, puxando a estrutura do garfo para cima ao longo do trilho-guia do mastro, enquanto impulsiona o garfo e a carga sobre ele para o levantamento.

Se o mastro precisar ser inclinado para acomodar a bifurcação ou descarga da carga, o cilindro de inclinação se estenderá e retrairá de acordo, fazendo com que o mastro se incline com a extremidade frontal como centro do círculo. Este design aumenta significativamente a flexibilidade da operação e reduz a dificuldade de operação.

Instruções de uso

1. Antes de usar, verifique se há sinais de danos ou desgaste no mastro.

2. Certifique-se de que a carga esteja distribuída uniformemente no mastro para evitar sobrecarga.

3. Ao utilizar uma empilhadeira, eleve lentamente o mastro até a altura necessária para evitar movimentos rápidos que podem fazer com que a carga escorregue.

4. Durante o manuseio, mantenha uma direção firme e evite curvas fechadas e paradas repentinas.

5. Após chegar ao destino, abaixe lentamente o mastro e certifique-se de que a empilhadeira esteja parada antes de descarregar a carga.

Dicas de segurança

-Não exceda o limite máximo de carga do mastro.

- Verifique regularmente os fixadores do mastro para garantir que não estejam soltos.

- Use equipamento de proteção individual adequado ao operar uma empilhadeira.

- Evite usar empilhadeira para movimentar mercadorias em declives para evitar que elas deslizem.

- Caso encontre qualquer anormalidade, pare de usá-lo imediatamente e entre em contato com um técnico profissional para inspeção.

Manutenção

- Limpe o mastro regularmente para evitar acúmulo de sujeira e detritos.

- Verifique as partes móveis do mastro e aplique a quantidade adequada de lubrificante, se necessário.

- Se o mastro estiver danificado ou muito desgastado, substitua-o a tempo para evitar riscos à segurança.

Para garantir a operação eficiente e segura do sistema de mastro da empilhadeira, a manutenção regular é essencial. Isso inclui lubrificar o mastro, verificar o grau de desgaste de cada peça de conexão, confirmar se a corrente e o cilindro não apresentam vazamentos e mantê-los em boas condições de funcionamento.

Em resumo, o mastro para empilhadeira é um sistema sofisticado que consiste em vários acessórios que trabalham em conjunto para melhorar a eficiência e a segurança das operações de movimentação. Para quem trabalha no setor de logística, um profundo conhecimento das funções e inter-relações desses acessórios não só ajudará a aprimorar as habilidades operacionais, como também permitirá a rápida resolução de problemas e reparos, quando necessário, para garantir a fluidez dos processos operacionais.

Se você precisar de acessórios para empilhadeiras, por favor

Contate-nos!

português

português português

português English

English français

français русский

русский español

español العربية

العربية

IPv6 rede suportada

IPv6 rede suportada