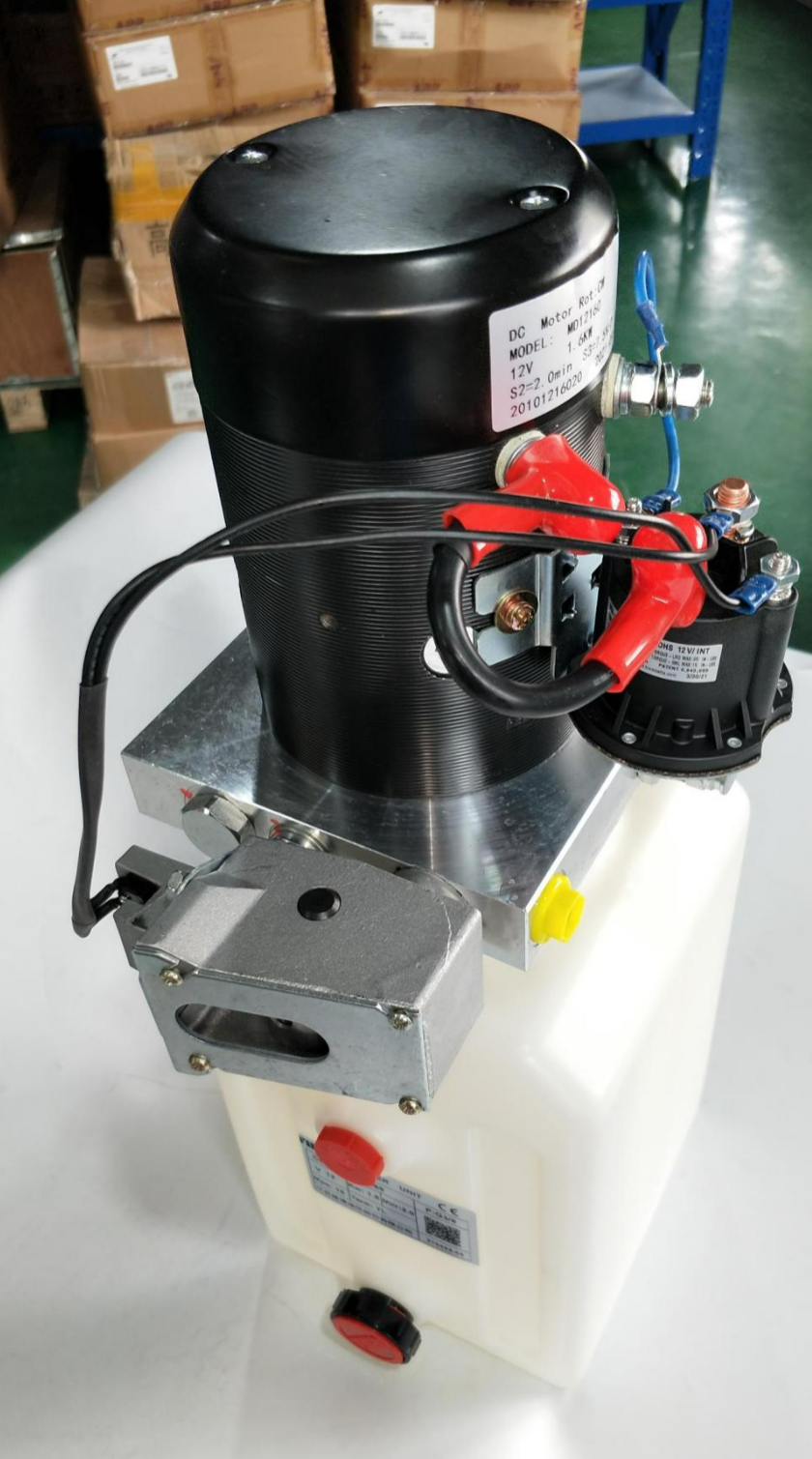

O conjunto unidade hidráulica da empilhadeira-estação de bombeamento é o componente principal do sistema hidráulico da empilhadeira.

Sua principal função é fornecer a pressão hidráulica e o fluxo necessários para que a empilhadeira acione cilindros hidráulicos, motores hidráulicos e outros atuadores hidráulicos para realizar diversas ações da empilhadeira.

Funções e benefícios do conjunto da estação de bombeamento:

01

Fornecendo energia hidráulica estável e confiável:

Conjuntos de estações de bombeamento de alta qualidade garantem energia hidráulica estável e confiável para empilhadeiras durante operações de elevação, inclinação e deslocamento, melhorando a eficiência operacional e a segurança.

02

Economia de energia e proteção ambiental:

O design e a tecnologia avançados reduzem efetivamente o consumo de energia e os custos operacionais, atendendo aos requisitos de conservação de energia e proteção ambiental.

03

Função de ajuste automático:

Um sistema de controle inteligente permite o ajuste automático e a otimização do sistema hidráulico, melhorando o desempenho da empilhadeira e o conforto do operador.

04

Economia de energia eficiente:

O conjunto da estação de bombeamento utiliza componentes hidráulicos e design de sistema altamente eficientes e econômicos, permitindo que a empilhadeira opere com maior eficiência e menor consumo de energia.

05

Diagnóstico e manutenção fáceis de falhas:

O conjunto da estação de bombeamento possui uma função de autodiagnóstico que identifica problemas prontamente e fornece avisos de manutenção, reduzindo o tempo de inatividade e melhorando a confiabilidade da empilhadeira e a eficiência da manutenção.

O conjunto unidade hidráulica e estação de bombeamento da empilhadeira desempenha um papel vital na operação da empilhadeira. Graças à sua potência hidráulica estável e confiável, características de economia de energia e respeito ao meio ambiente, além de funções inteligentes, ele fornece um forte suporte para a operação eficiente da empilhadeira.

O conjunto de unidade hidráulica para empilhadeira e estação de bombeamento não é apenas potente, mas também muito prático e confiável. Seja em operações de armazém ou transporte logístico, ele é o seu auxiliar indispensável! Deixe-me apresentar nosso conjunto de estação de bombeamento comum.

Montagem da estação de bombeamento MIMA:

Conjunto de estação de bombeamento MIMA, MD24080AN (24 V/800 W),

Veículo: Caminhão-palete MIMA TF15

Montagem da estação de bombeamento de Hangcha

Conjunto de estação de bombeamento Hangcha MD24080AN (24 V/800 W)

Modelo: Empilhadeira/Palete Econômica Hangcha CBD20-AEC1/AEC1S, CDD12/14/16-AEC1(-B)/AEC1S(-B) (-2013.10)

Montagem da estação de bombeamento Jiali/Lonking

Conjunto de estação de bombeamento Jiali/Lonking DYB0.8DJ-W (24 V/0,84 kW)

Modelo: Jiali Pequeno King Kong/Lonking Pequeno Elfo

Montagem da estação de bombeamento Liftstar

Conjunto de estação de bombeamento Liftstar/FC 17G-300

Veículos compatíveis: Lida 17G/Lida 17H (instalação vertical)

Montagem da estação de bombeamento noblelift

M208V (24V/800W) Noblelift, marca do motor: Hydro-Tek

Conjunto de estação de bombeamento noblelift MD24080AN (24 V/800 W)

Montagem da estação de bombeamento Xilin

Conjunto de estação de bombeamento Xilin Haipu 24V/800W

Empilhadeira totalmente elétrica Xilin CBD20H, Empilhadeira de passeio Xilin CBD20R-3

MD24080AE (24 V/800 W)

Em resumo, o conjunto unidade hidráulica-estação de bombeamento, com sua alta eficiência, forte estabilidade, fácil manutenção e adaptabilidade, demonstrou excelente desempenho em uma ampla gama de áreas. Seja em logística e armazenagem, construção ou linhas de produção, ele fornece suporte de energia estável e confiável, tornando-se o "coração" indispensável da empilhadeira. Com o avanço contínuo da tecnologia e o crescimento da demanda do mercado, se você precisa de um conjunto de estação de bombeamento para empilhadeira, entre em contato conosco.

Contate-nos!

português

português português

português English

English français

français русский

русский español

español العربية

العربية

IPv6 rede suportada

IPv6 rede suportada